総合型選抜 落ちたら 公募推薦

総合型選抜(AO入試)に関してこんな悩みはありませんか?

- 総合型選抜を受けたいけど、小論文や志望理由書についてどう対策してよいかわからない

- 自分が行きたい希望の大学はあるけど、今のままで受かるのか不安でしかたない

- 部活動・ボランティア活動の実績を生かしたいが、どのようにアピールすればよいかわからない

- 大した活動実績がないのに、総合型選抜を受けたいと思っているけど大丈夫なのか

このような悩みのある方には、総合型選抜専門の対策塾がおすすめです。

一般的な大学受験塾とは異なり、志望理由書や小論文の書き方など、総合型選抜の試験内容に特化して対策を行ってくれる塾です。

大学別に対策をとっていただけるので、目標の大学合格へ一歩前進できます。

ここでは、特におすすめの総合型選抜専門対策塾を厳選して紹介します。

実は、私も総合型選抜を受けた経験があります。

最初は自分で対策できると思い、参考書片手に自習でやってきましたが、志望理由書や小論文の書き方等については、自力での学習は難しかったです。

やはり客観的にみてもらえる人がいないと、正しく受験対策できているとはいえない状況でした。

総合型選抜専門塾を利用し始めてから、

志望理由書や小論文の書き方などの対策はもちろんのこと、

自分が将来何をしたいかについてもしっかり考えることができるようになり、入試の面接において、自信をもってアピールすることができるようになりました。

大学生となった今では、自分の夢につながる勉強が出来て、毎日楽しいキャンパスライフを送っていて、本当に総合型選抜専門の塾に通っていてよかったと感じています。

総合型選抜専門対策塾を選ぶポイント

総合型選抜専門対策塾といっても、適当なところを選んでしまうと、あとで後悔してしまうことになりかねません。総合型選抜専門対策塾を選ぶ際のポイントを満たすところがおすすめです。

- 合格実績が十分にあるか

- 一人一人の志望校に合わせた指導をしてくれるか

- 総合型選抜(AO入試)に特化した教材があるか

- 自分の将来について、学生自身が相談しやすい環境であるか

- 浪人生でも受け入れ可能であるか

これらのポイントを押さえておけば、塾選びに失敗することはなくなります。

総合型選抜専門塾おすすめ3選

AOI

AOIは業界No.1の合格率を誇る総合型選抜(AO入試)専門塾。2022年の合格率は95.2%です。

関東・関西に4校舎を展開しています。オンライン校もあるので地方や海外在住の学生の対応も可能。

高い合格率がありながら、授業料が他社と比べてリーズナブルなので人気です。

標準的な授業料は年間48万円~となっていますが、必要なコマ数が少ない場合にはこれよりも安くなります。

詳細データ

| 対象 | 高校生・浪人生 |

|---|---|

| 授業料 | 48万円~(年間) |

| 授業形態 | 個別 |

| 対応入試形態 | オンライン校、渋谷校、大阪校、京都校、西宮北口校 |

| 教室 | 渋谷、上野、日吉 |

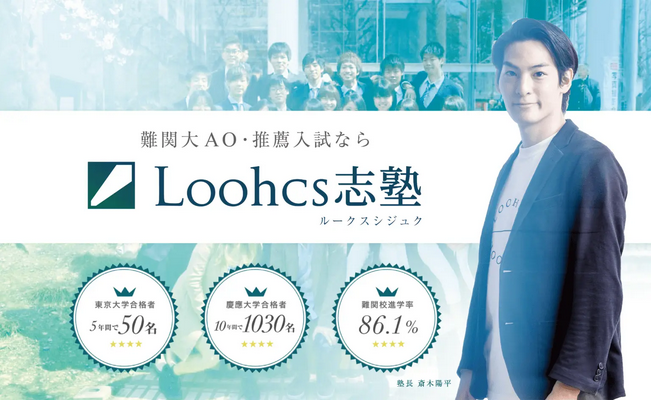

ルークス志塾(旧:AO義塾)

難関大学総合型選抜(AO入試)対策の大手塾。

志望校合格率87.2%という高い合格率を出し続けている。

特に早慶上智への合格実績が多数あり、2022年度における慶應義塾大学の合格者を124名輩出している。

詳細データ

| 対象 | 高校生 |

|---|---|

| 授業料 | 平均40万円(年間)、月額76,780円 |

| 授業形態 | 集団 |

| 対応入試形態 | 総合選抜型・AO推薦入試・一般入試 |

| 教室 | 首都圏11教室(代々木、四谷、池袋、目黒、自由が丘、下北沢、町田、吉祥寺、横浜、青葉台、柏) |

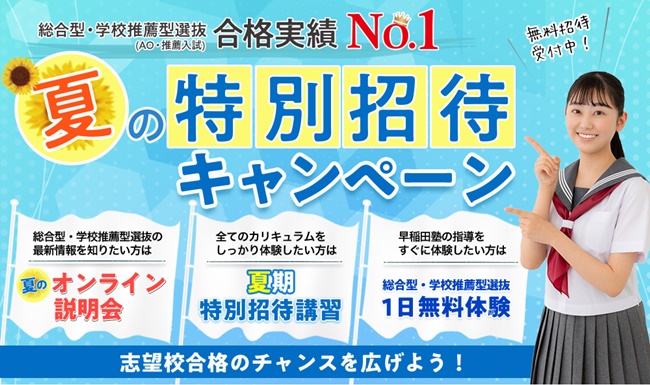

早稲田塾

東進ネットワークに所属する学習塾。

一般入試対策を行っている中、コースの1つとして、「総合型・学校推薦型選抜(AO・推薦入試)特別指導」コースが設置されている。

一人一人の志望大学に合わせたオリジナル出願戦略を提案。大学ごとの様々な入試形態に対応し指導。

詳細データ

| 対象 | 高校2~3年生 |

|---|---|

| 授業料 | 非公表 |

| 授業形態 | 集団 |

| 対応入試形態 | 総合選抜型・AO推薦入試・一般入試 |

| 教室 | 12教室(池袋、大崎、自由が丘、新宿、四谷、吉祥寺、町田、青葉台、藤沢、横浜、柏、津田沼) |

おすすめの総合型選抜専門塾は「AOI」

AOIは業界No.1の合格率を誇る総合型選抜(AO入試)専門塾です。 (2022年合格率95.2%)

関東・関西に4校舎を展開しているのみならず、オンライン校もあり、地方でAO入試専門の塾がないという方でも利用できます。

高い合格率がありながら、授業料が他社と比べてリーズナブルなので人気があります。

AOIのメリット

AOIを利用するメリットをまとめました。

- メンターとカリキュラムによるフルオーダーメイド授業

- 独自のノウハウを詰め込んだ映像授業・ドリル

- 通常の塾とは異なる自由な環境で学習できる

- 総合型選抜に必要な対策の全てに対応

- 受験相談を完全個別で実施できる

- オンライン校がある

- 浪人生も受け入れている

メンターとカリキュラムによるフルオーダーメイド授業が受けられる

学生の志望校への合格と夢をサポートするメンターの存在と、1人1人の夢の実現に合わせたカリキュラムによって学習をすすめられるフルオーダーメイド授業を1対1のマンツーマンで受けることができます。

メンターの80%が実際に総合型選抜(AO入試)を経験したことがある大学生なので、より親身になって総合型選抜対策をサポートしてくれます。

独自のノウハウを詰め込んだ映像授業・ドリルがあり、授業の理解が深められる

業界No.1合格率を誇るAOI独自のノウハウを詰め込んだ160本以上の映像授業や、授業理解を深めるための自己分析・志望理由書・小論文対策ドリルがあり、総合型選抜に特化した対策をしっかり進めることができます。

通常の塾とは異なる自由な環境で学習できる

通常の塾のように、黒板の前に机と椅子が並べられた環境ではなく、校舎は壁や柱を極限までなくした開放的な空間となっており、リラックスした自由な環境の下に学習できます。堅苦しくないので、自由に学習したい学生にとっては心地のよい環境になります。

総合型選抜に必要な対策の全てに対応できる(指定校や公募も対応可能)

探求学習・自己分析、志望理由書、小論文、面接・プレゼン、英語資格など総合型選抜に必要な対策全てに対応することができます。

特にAOIは他社と比べて小論文と志望理由書が強く、自己分析に重きをおいています。 また、指定校推薦や学校推薦型選抜、公募制推薦で受験対策にも対応できます。

受験相談を完全個別で実施できる

AOIでは、総合型選抜への理解や具体的な対策方法、受験適正などを行う受験相談を完全個別で1時間受けることができます。

他塾では活動実績をすでに持っている子が多く在籍していますが、AOIは受験生一人一人の現状を確認した上で、実績の作り方も1から教えてもらえるので、これから総合型選抜を考えている方も安心して学習することができます。

オンライン校がある

地方在住の学生はもちろん、校舎へ通う時間がない部活性や一般入試の予備校との両立をしたい方などが利用できるオンライン校があります。 オンラインでの指導内容も、校舎での指導内容と同様、1対1の個別授業や160本以上の映像授業などの指導を受けることができます。

浪人生も受け入れている

浪人生も時間の使い方によっては、総合型選抜対策も有利に進められます。 AOIでは他の塾では受け入れしていない浪人生も受け入れています。

AOIのデメリット

AOIは総合型選抜に特化した塾であるため、他の塾であるような一般入試対策のカリキュラムはありません。

一般入試対策もしっかりとりたいという方はLoohcs志塾や早稲田塾など別の塾がおすすめです。

ただ総合型選抜対策を行うことで、一般入試でも通用する論理的思考力・文章力を身に付けることは可能です。

AOIの公式サイトはこちら総合型選抜専門塾を選ぶポイントを詳しく紹介

上記でも説明しましたが、総合型選抜専門塾を選ぶポイントは次の5つです。

- 合格実績が十分にあるか

- 一人一人の志望校に合わせた指導をしてくれるか

- 総合型選抜(AO入試)に特化した教材があるか

- 自分の将来について、学生自身が相談しやすい環境であるか

- 浪人生でも受け入れ可能であるか

これらのポイントについて詳しく紹介します。

合格実績が十分にあるか

志望校合格のためには、やはり合格実績が十分になるかは確認すべき事項になります。

特に自分が行きたい特定大学がある場合は、その大学への合格実績が高い塾で学習する方が、合格するにはより有利になります。

一人一人の志望校に合わせた指導をしてくれるか

学生に志望校に合わせたしっかり個別に指導してもらえるのかが重要です。1対1の個別授業を取り入れている塾を選ぶようにするとよいです。

総合型選抜(AO入試)に特化した教材があるか

総合型選抜対策といっても、自己分析、志望理由書、小論文、面接・プレゼン、英語資格などがあり、志望校に合わせて必要な対策も様々です。それぞれに合わせて特化した教材や授業がある塾を選ぶのもポイントです。

自分の将来について、学生自身が相談しやすい環境であるか

総合型選抜を受けるにあたって、自己分析をした上で志望校を決めるのも重要です。自分の将来の夢や強みについて、学生自身が相談しやすい環境がある塾を選ぶようにするとよいです。

特に、まだ志望校が決まっていない、活動実績を持っていない学生の場合、自分自身について相談しやすい塾であるのかは重要になります。

浪人生でも受け入れ可能であるか

総合型選抜対策塾の多くは、高校生を対象としており、浪人生は受け入れてもらえないところがほとんどです。

浪人生の場合、時間の使い方によっては、総合型選抜でも有利になります。浪人生で総合型選抜を考えている学生は、浪人生も受け入れてもらえる塾を選びましょう。

総合型選抜対策塾おすすめ3選へ